In the assembly design, if there are abnormalities and forced assembly such as mounting surface deformation, product performance will be reduced.

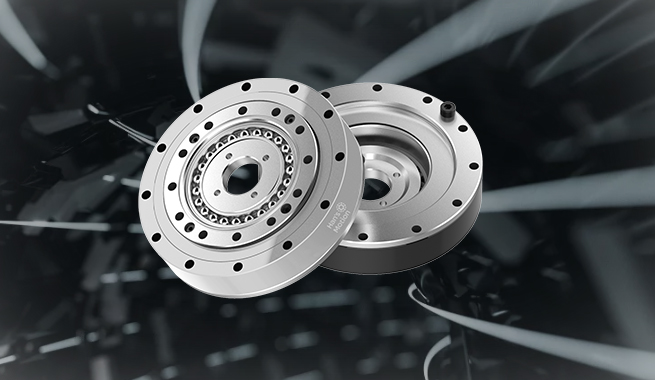

lb give full play to the excellent performance of the China harmonic reducer, please pay attention to the following matters and ensure the recommended accuracy of the assembly housing as shown in the following figure and the table below.

Mounting surface deflection and deformation.

The foreign substance occurs.

The surrounding rough edges, uplift, and abnormal position of screw holes on the mounting holes.

The chamfer of the recessed circle is insufficient.

The degree of roundness of the recessed circle is abnormal.

When comparing cycloidal gear drives and harmonic drives, two distinct mechanisms for power transmission, several factors come into play.

A cycloidal gear drive, also known as a cyclo drive or cycloidal drive, employs a set of pins and cam followers to create eccentric motion, resulting in speed reduction. On the other hand, a harmonic drive utilizes a flexspline, a harmonic drive wave generator, and a circular spline to achieve high gear reduction ratios.

In terms of performance, harmonic drives excel in precision and backlash-free operation. The unique wave generator in harmonic drives allows for smooth and accurate motion control, making them ideal for applications requiring high positioning accuracy, such as robotics and automation. Cycloidal drives, while less precise, offer high torque capacities and are better suited for applications that prioritize torque output over positioning accuracy.

Size and weight considerations differ as well. Harmonic drives are renowned for their compactness and lightweight construction, making them advantageous in space-constrained applications. Cycloidal drives tend to be bulkier due to their construction with pins and cam followers, making them suitable for applications where size is not a limiting factor.

It's important to consider cost as well. The reductor harmonic drive generally tends to be more expensive due to its intricate construction and precision engineering. Cycloidal drives, being simpler in design, are often more cost-effective.

In summary, both cycloidal gear drives and harmonic drives including robot harmonic drive offer unique advantages depending on the specific application requirements. Harmonic drives excel in precision and compactness, while cycloidal drives prioritize high torque output and cost-effectiveness. Understanding the needs of the application is crucial in determining which drive system is most suitable.

A cycloidal gearbox works by utilizing a set of pins and cam followers to generate eccentric motion. The input shaft transfers rotation to a high-speed shaft, which drives an eccentric cam. The cam followers connected to the cam engage with the cycloidal disc, causing it to oscillate. This motion is then transferred to the output shaft, resulting in speed reduction and torque multiplication. The unique eccentric motion of the cycloidal gearbox provides advantages such as high torque capacity and durability.