HMCG-I consists of three basic components: flexible gear, rigid gear, and wave generator. The flexible gear is a cup-shaped standard structure, and its input shaft directly cooperates with the inner hole of harmonic drive gear box and connects with it through flat key or fastening screw."

Three basic components

Compact design

Zero backlash

Input and output coaxial

Excellent positioning accuracy and rotation accuracy

30%higher torque capacity than the HMCS series

43%longer lifetime than the HMCS reductor harmonic drive series

Competitive quality with the above advantages of strain wave gearing, inquiry Hansmotion to buy harmonic drive

Industrial Robots (harmonic drive robot)

Grinding Machines

Machining Centers

Rehabilitation

Humanoid Robots

| Model | Reduction ratio | Rated torque at input 2000r/min | Permissible peak torque at start / stop | Permissible max.value | Instantaneous permissible max. torque | Permissible max.rotational speed | Permissible ave. rotational speed | Back clearance (arc sec) | Transmission accuracy (arc sec) |

| Nm | Nm | Nm | Nm | r/min | r/min | ≤ | ≤ | ||

| 14 | 50 | 7 | 23 | 9 | 46 | 8000 | 3500 | 20 | 90 |

| 80 | 10 | 30 | 14 | 51 | 20 | 90 | |||

| 100 | 10 | 36 | 14 | 70 | 10 | 90 | |||

| 17 | 50 | 21 | 44 | 34 | 91 | 7000 | 3500 | 20 | 90 |

| 80 | 29 | 56 | 35 | 113 | 20 | 90 | |||

| 100 | 31 | 70 | 51 | 143 | 10 | 90 | |||

| 20 | 50 | 33 | 73 | 44 | 127 | 6000 | 3500 | 20 | 60 |

| 80 | 44 | 96 | 61 | 165 | 20 | 60 | |||

| 100 | 52 | 107 | 64 | 191 | 10 | 60 | |||

| 120 | 52 | 113 | 64 | 161 | 10 | 60 | |||

| 25 | 50 | 51 | 127 | 72 | 242 | 5500 | 3500 | 20 | 60 |

| 80 | 82 | 178 | 113 | 332 | 20 | 60 | |||

| 100 | 87 | 204 | 140 | 369 | 10 | 60 | |||

| 120 | 87 | 217 | 140 | 395 | 10 | 60 | |||

| 32 | 50 | 99 | 281 | 140 | 497 | 4500 | 3500 | 20 | 60 |

| 80 | 153 | 395 | 217 | 738 | 10 | 60 | |||

| 100 | 178 | 433 | 281 | 841 | 10 | 60 | |||

| 120 | 178 | 459 | 281 | 892 | 10 | 60 | |||

| 40 | 50 | 178 | 523 | 255 | 892 | 4000 | 3000 | 10 | 60 |

| 80 | 268 | 675 | 369 | 1270 | 10 | 60 | |||

| 100 | 345 | 738 | 484 | 1400 | 10 | 60 | |||

| 120 | 382 | 802 | 586 | 1530 | 10 | 60 | |||

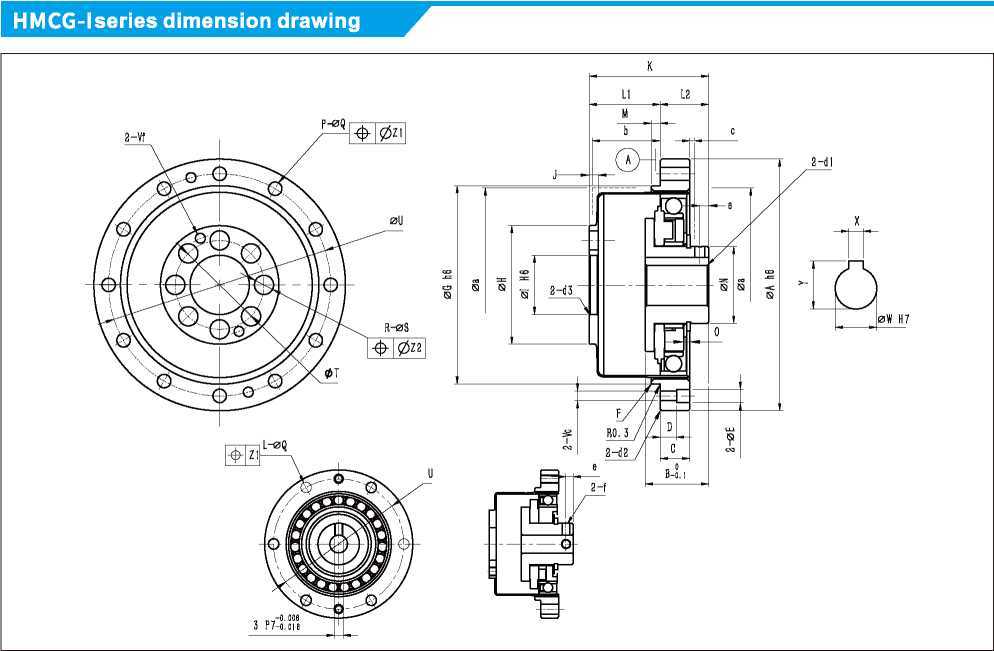

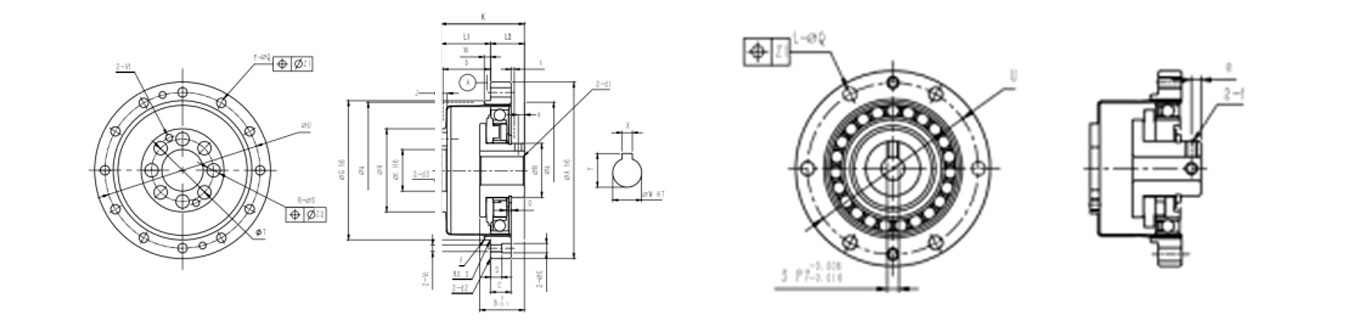

| Symbol/Model | 14 | 17 | 20 | 25 | 32 | 40 | |

| ∅A H6 | 50 | 60 | 70 | 85 | 110 | 135 | |

| B _−0.1^0 | 18.5 | 20.7 | 21.5 | 21.6 | 23.6 | 29.7 | |

| C | 6 | 6.5 | 7.5 | 10 | 14 | 17 | |

| D | - | - | 4 | 6 | 7 | 7 | |

| ∅E | - | - | 3.6 | 4.5 | 5.5 | 6.6 | |

| F | C0.3 | C0.4 | C0.4 | C0.4 | C0.4 | C0.4 | |

| ∅G H6 | 38 | 48 | 54 | 67 | 90 | 110 | |

| ∅H | 23 | 27.2 | 32 | 40 | 52 | 64 | |

| ∅I H6 | 11 | 10 | 16 | 20 | 26 | 32 | |

| J | 2.4 | 3 | 3 | 3 | 3.2 | 4.1 | |

| K | 28.6±0.2 | 32.2±0.2 | 33.5±0.2 | 37.2±0.2 | 44±0.2 | 53±0.2 | |

| L1 | 17.5 | 20 | 21.5 | 24 | 28 | 34 | |

| L2 | 11.1 | 12.2 | 12 | 13.2 | 16 | 19 | |

| M | 2 | 2.5 | 3 | 3 | 3 | 4 | |

| ∅N | 14 | 18 | 21 | 26 | 26 | 32 | |

| O | 0.4 | 0.3 | 0.1 | 2.1 | 2.5 | 3.3 | |

| P | 8 | 16 | 16 | 16 | 16 | 16 | |

| ∅Q | 3.5 | 3.4 | 3.5 | 4.5 | 5.5 | 6.6 | |

| R | 6 | 6 | 8 | 8 | 8 | 8 | |

| ∅S | 4.5 | 5.5 | 5.5 | 6.6 | 9 | 11 | |

| T(PCD) | 17 | 19 | 24 | 30 | 40 | 50 | |

| U(PCD) | 44 | 54 | 62 | 75 | 100 | 120 | |

| Vc | M3 | M3 | M3 | M4 | M5 | M6 | |

| Vf | M3 | M3 | M3 | M4 | M5 | M6 | |

| ∅W | standard(H7) | 6 | 8 | 11 | 14 | 14 | 14 |

| maximum size | 8 | 10 | 13 | 15 | 15 | 15 | |

| XJS9 | - | - | 4 | 5 | 5 | 5 | |

| Y | - | - | 12.8﹢0.10 | 16.3﹢0.10 | 16.3﹢0.10 | 16.3﹢0.10 | |

| ∅Z1 | 0.25 | 0.2 | 0.25 | 0.25 | 0.25 | 0.25 | |

| ∅Z2 | 0.25 | 0.25 | 0.25 | 0.3 | 0.5 | 0.25 | |

| ∅a | 38 | 45 | 53 | 66 | 86 | 106 | |

| b | 17.1 | 19 | 20.5 | 23 | 26.8 | 33 | |

| c | 1 | 1 | 1.5 | 1.5 | 1.5 | 2 | |

| Cd1 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | |

| Cd2 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | |

| Cd3 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| e | 2.5 | 3 | - | - | - | - | |

| f | M3X4 | M3X6 | - | - | - | - | |

| weight(kg) | 0.1 | 0.17 | 0.26 | 0.43 | 0.91 | 1.8 | |