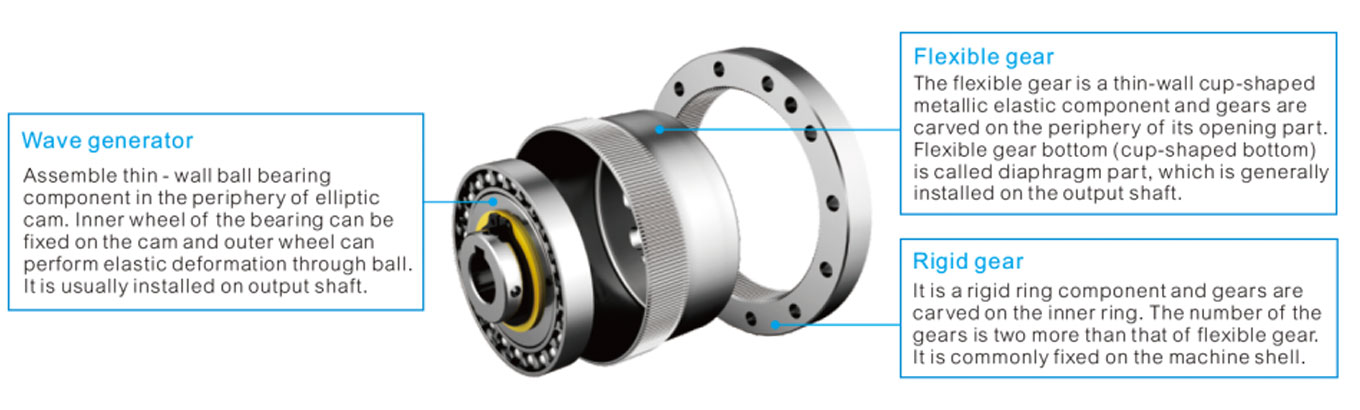

Harmonic Gear Drive Reducer Advantages

Harmonic gear drive reducers offer several advantages in gear reduction drives, making them a popular choice for various applications. PICEA MOTION is a reputable harmonic gear drive reducer supplier, providing reliable and high-quality products.

One key advantage of harmonic drive gear box is their compact size and lightweight construction. Compared to traditional gearboxes, harmonic drives offer a higher gear reduction ratio within a smaller package. This feature makes them ideal for applications where space is limited or weight needs to be minimized.

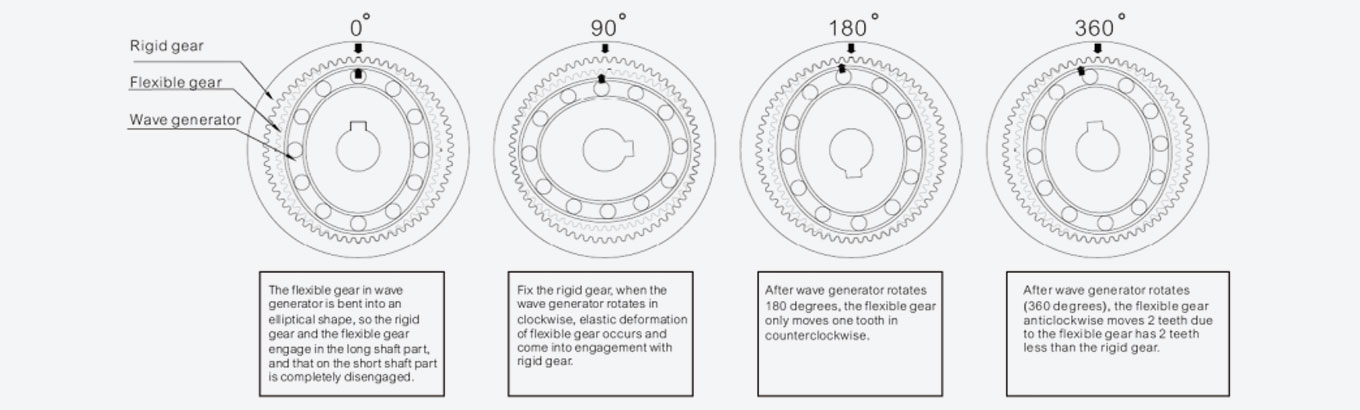

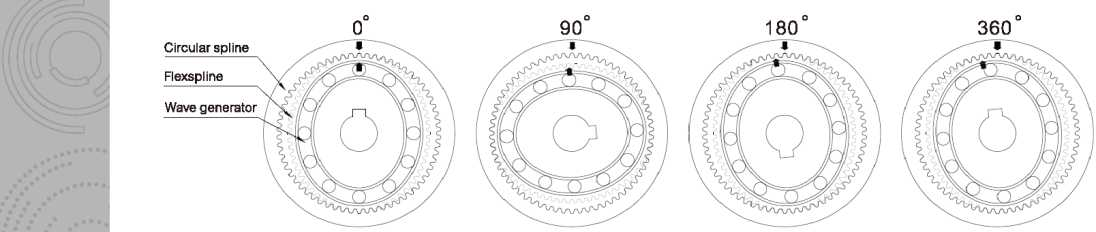

Additionally, the harmonic drive gear delivers excellent precision and backlash-free operation. The unique design of the reductor harmonic drive ensures smooth and accurate motion transmission, resulting in improved positioning accuracy and reduced vibration. This makes it suitable for applications that require high precision, such as robotics, automation, and aerospace systems.

Furthermore, harmonic gearing drives offer high torque-to-weight ratios, enabling efficient power transmission. Power drive gearbox can handle high torque loads while maintaining a compact and lightweight design, making them energy-efficient and cost-effective.

By purchasing harmonic gear drive from PICEA MOTION, customers can benefit from their expertise as a trusted harmonic drive company. PICEA MOTION provides reliable harmonic gear drive reducer and exceptional customer service, ensuring that customers receive the best harmonic gear drives for their specific needs.

In summary, the reductor harmonic drive offers advantages such as compact size, precision, high torque-to-weight ratios, and backlash-free operation. PICEA MOTION serves as a reliable supplier for those looking to buy harmonic drives, providing top-quality products and comprehensive support for harmonic speed reducer gearboxes.

Harmonic Gear Drive Reducer Applications

Harmonic gear drive reducers find wide-ranging applications in gear reduction drives, making them highly versatile and sought after in various industries. PICEA MOTION, a reputable harmonic gear drive supplier, offers the option suitable for diverse harmonic drive applications, including those in robotics, industrial laser cutting, and packaging food processing.

In robotics, harmonic gearbox drives are commonly utilized due to their compact size, high precision, and backlash-free operation. The robot speed reducer enables accurate and smooth motion control, enhancing the performance and efficiency of robotic systems.

For industrial laser cutting applications, gear reduction drive plays a crucial role in translating the rotational motion of the motor to precise linear motion. The precise movement control and high torque capabilities of the reductor harmonic drive ensure accurate and efficient laser cutting processes.

In the packaging and food processing industry, harmonic gear drives are employed to achieve precise and synchronized movements in packaging machines. They enable consistent and reliable operation, ensuring smooth product handling and packaging.

PICEA MOTION serves as one of the reliable reduction gears suppliers, offering types of gear boxes tailored to specific application requirements. With their expertise and quality products, PICEA MOTION provides customers with optimal solutions for speed reducer gearboxes in a variety of applications, including robotics, industrial laser cutting, and packaging food processing.

How to Make A Gear Reduction Box?

Creating a reduction drive gearbox involves a systematic process to ensure precision and functionality.

Select Gear Ratios: Begin by determining the desired harmonic gear drive ratios for the reduction box. This involves understanding the speed and torque requirements for your specific application.

Gather Materials: Acquire the necessary materials, including gears, shafts, bearings, and a housing. Ensure the materials are durable and can withstand the intended load and environmental conditions.

Design the Gear Train: Develop a harmonic drive gear train layout based on the selected ratios. This involves arranging gears on shafts and calculating the number of teeth to achieve the desired reduction.

Assemble Gears and Shafts: Place the harmonic gear drive reducers on the designated shafts, ensuring proper alignment and spacing. Use precision tools to secure gears in place, promoting smooth rotation.

Incorporate Bearings: Integrate bearings into the housing to support the rotating shafts. Proper bearing installation is crucial for reducing friction and ensuring longevity.

Seal the Housing: Seal the housing to protect the gear speed reducers and bearings from contaminants. This step is critical for maintaining the efficiency and durability of the gear reduction box.

Test and Adjust: Conduct thorough testing to ensure the reduction drive gearbox operates as intended. Make any necessary adjustments to achieve the desired performance, addressing issues such as noise or vibration.

Lubrication: Apply suitable lubricants to the gears and bearings to minimize friction and reduce wear. Regular maintenance, including lubrication, is essential for prolonging the life of the reduction drive gearbox.