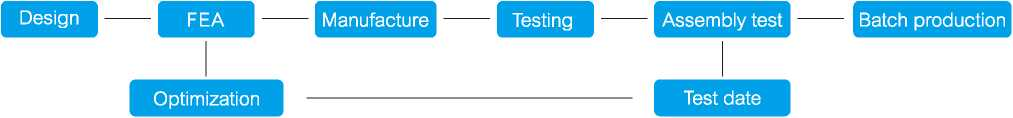

Based on theoretical calculation and finite element analysis, combined with the sophisticated detection system to obtain massive measured data, and by means of mult-objective regression optimization, Han's Motion team successfully broke through the non-standard design difficulties of double arc tooth profile and developed a breakthrough harmonic.

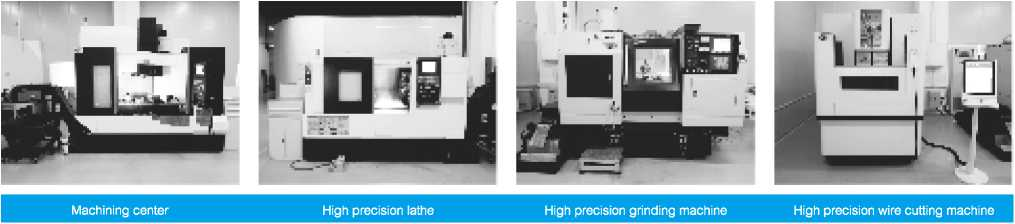

As one of the harmonic drive manufacturers, we imported a batch of world first-class processing and manufacturing equipment, so we can provide a strong guarantee for the production team to produce high-quality PRODUCTS.

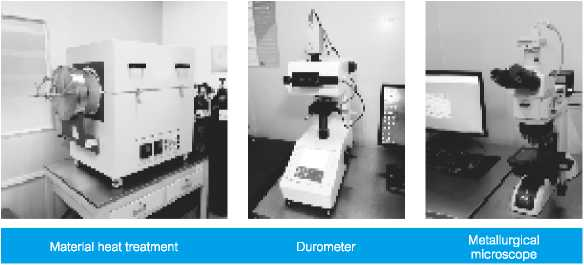

The key component flex spline is made of imported high-quality materials and adopts unique multi-process technology for heating processing.By optimizing the mechanical properties of the material, the precision of products can be guaranteed and the service life of the flex spline can be greatly improved.

As a key component of industrial production automation, the harmonic reducer must pass a series of stringent tests before it can be delivered.

Each finished product of Han's Motion harmonic drive, each process before leaving the factory is subjected to high standards and high quality control. After strict rigorous testing, it will eventually reach the customer.