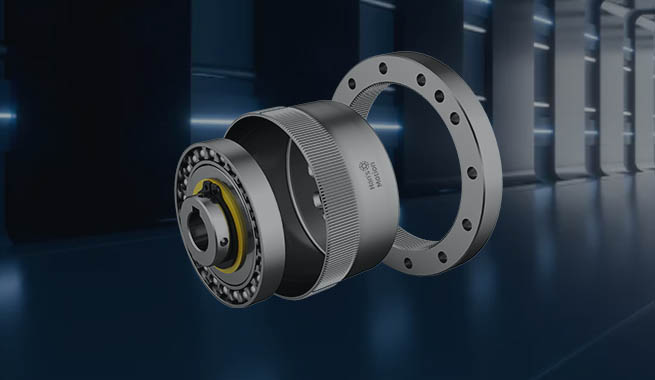

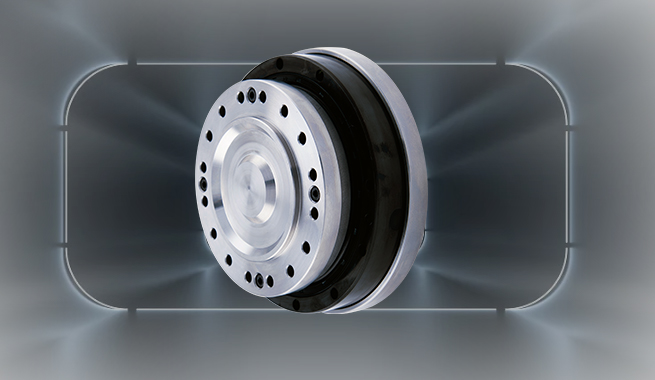

Focus on the lightweight and compact size of the harmonic reducer. Ultra-flat series products enter the market.

Established customer relations with Zhuhai Gree, Wasu Robot, Zhejiang Qixing, and Dongguan QUADRO Robot; Products had gradually obtained recognition in the market.

PICEA harmonic reducer was awarded the "Red Sail Award for Industrial Design".

The development and testing of short-tube, light-weight, and high-torque harmonic reducers were finished, being in the final verification phase.

6 series (more than 100 types) of harmonic reducers were successively manufactured, formally entering the market.

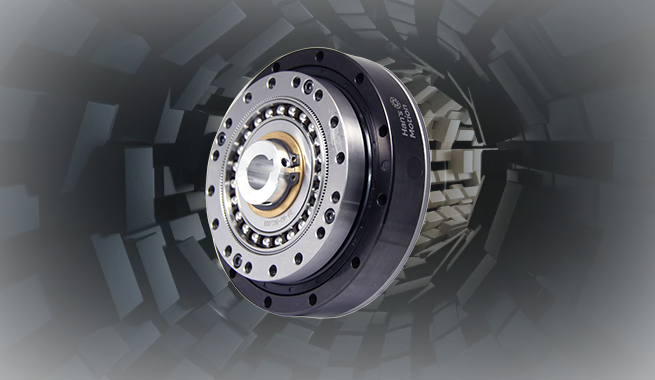

The using tests of multiple mainstream robot manufacturers were finished. Several key technologies, including product precision, lifetime stability, and noise control, of PICEA harmonic reducer, had reached the same product lever as foreign companies, and the technical index ranked first in China.

All tests were basically finished, establishing a complete internal inspection standard process.

Established PICEA Motion R & D Production Base that introduced a batch of world-class processing and testing equipment from abroad, forming scale production

Established close industry-university cooperation with Tokyo University and Tsukuba University

PICEA Motion was set up.

All test results had reached the standards after a mass of measured data. The precision harmonic reducer reaching the using standard of the industrial robot had been produced and continuously gone through tests and inspections by many domestic and foreign institutions.

Pilot production, applied to robot test and inspection inside the company.

Successfully broke through the difficulties in the non-standard design of double-arc tooth profiles, designed and manufactured the prototype of the first harmonic reducer, and began to make repeated tests and continuous improvement.

A group of professional technicians gathered in Han’s Laser and set up the R & D team to develop harmonic drive technology in the industrial robot field from scratch.